Fluke 805 FC

$1.129Fluke Connect Vibration Meter Order #: 805 FC Mfg #: 4489229

Showing 1–9 of 29 results

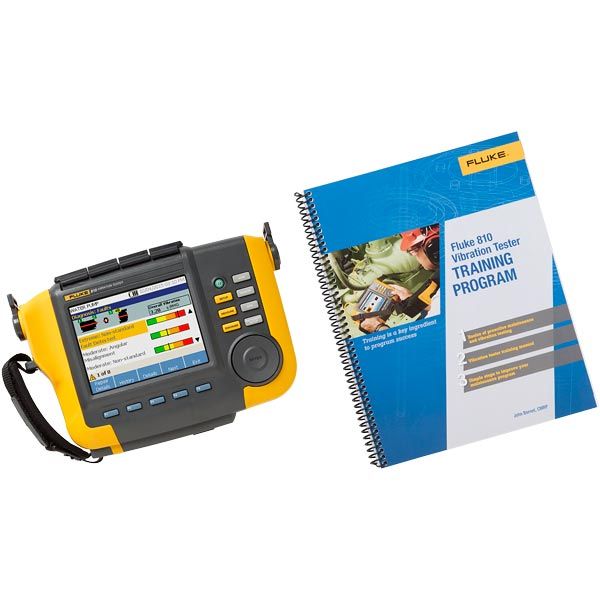

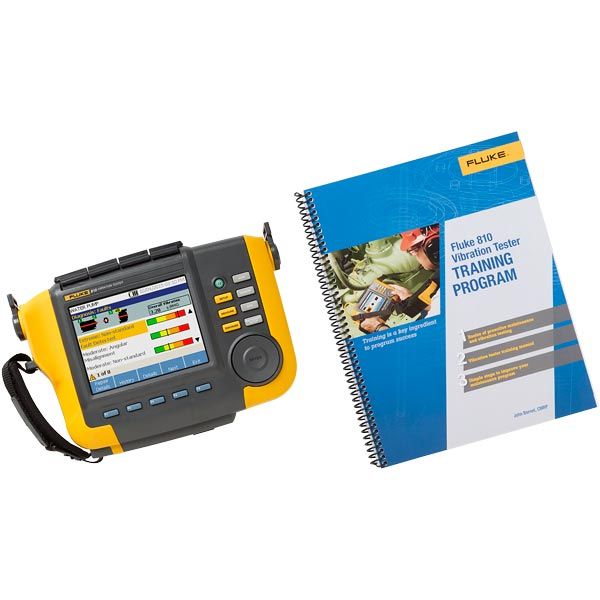

Control unplanned downtime, prevent recurring problems, set repair priorities and manage your resources with an entirely new approach to vibration testing. The Fluke 810 helps you locate and diagnose common mechanical problems and prioritize repair actions with no prior machine history.

Introduction to Fluke Vibration Fluke vibration refers to the measurement and analysis of mechanical vibrations using specialized tools and equipment developed by Fluke, a globally recognized leader in precision measurement technology. Vibration measurement is a critical aspect of predictive maintenance and condition monitoring in various industries, including manufacturing, aerospace, and energy. Understanding the principles of vibration measurement involves recognizing how oscillatory motions in machinery components can indicate potential failures or inefficiencies. Accurate vibration analysis is essential for maintaining the health of machinery. It helps in early detection of mechanical issues such as misalignment, imbalance, bearing failures, and gear defects. By identifying these problems early, maintenance teams can prevent costly downtime and extend the lifespan of equipment. Fluke’s vibration measurement tools are known for their reliability and precision, making them indispensable in the toolkit of maintenance professionals. The basic principles of vibration measurement include the detection of amplitude, frequency, and phase of the oscillatory motion. These parameters are captured using accelerometers, which convert mechanical vibrations into electrical signals. The data is then analyzed to diagnose the condition of the machinery. Fluke provides a range of vibration measurement tools, including portable vibration testers, vibration meters, and sophisticated vibration analyzers, each designed to cater to different levels of diagnostic needs. Fluke’s dedication to innovation and quality makes their vibration analysis tools effective in detecting and diagnosing mechanical issues with high accuracy. Their equipment is engineered to withstand harsh industrial environments, ensuring durability and consistent performance. The importance of accurate vibration analysis in predictive maintenance cannot be overstated, as it contributes significantly to the operational efficiency and reliability of industrial machinery. Applications and Benefits of Fluke Vibration Analysis Fluke vibration analysis has become an indispensable tool across various industries, including manufacturing, automotive, aerospace, and energy. In manufacturing, for instance, vibration analysis is critical in monitoring the condition of machinery. By identifying early signs of wear and tear, maintenance teams can prevent equipment failure, thereby reducing downtime and extending the life of machinery. This proactive approach not only enhances productivity but also leads to significant cost savings. In the automotive sector, Fluke vibration analysis is used extensively to diagnose issues within vehicle components. From engine imbalances to misaligned driveshafts, the precision of vibration analysis ensures that potential problems are detected and rectified before they escalate. This results in improved vehicle performance and reliability, reinforcing customer satisfaction and reducing warranty claims. The aerospace industry also benefits significantly from vibration analysis. Aircraft components are subject to stringent safety and performance standards, and Fluke vibration tools provide the accuracy needed to meet these requirements. By regularly monitoring the vibration levels of critical parts such as turbines and rotors, maintenance teams can ensure the safety and efficiency of aircraft operations. This not only mitigates the risk of in-flight failures but also optimizes maintenance schedules. In the energy sector, particularly in power plants and wind farms, vibration analysis plays a pivotal role in the maintenance of turbines and generators. Fluke vibration tools help in detecting anomalies such as bearing failures and misalignments, which can lead to catastrophic failures if left unchecked. By integrating vibration analysis into routine maintenance programs, energy companies can enhance the reliability of their operations and achieve substantial cost savings. Case studies have demonstrated the tangible benefits of implementing Fluke vibration tools. For instance, a manufacturing plant reported a 30% reduction in unplanned downtime and a 20% increase in machinery life after incorporating vibration analysis into their maintenance strategy. Similarly, an automotive company experienced a 25% decrease in warranty claims by utilizing vibration diagnostics to enhance vehicle quality. Best practices for integrating Fluke vibration analysis into routine maintenance programs include regular training for maintenance personnel to ensure effective use of the tools. Continuous monitoring and data analysis are also essential to identify trends and make informed maintenance decisions. By fostering a culture of proactive maintenance, companies can maximize the benefits of Fluke vibration analysis, ultimately leading to improved operational efficiency and cost-effectiveness.

Understanding the Fluke 810: Features and Specifications The Fluke 810 is a sophisticated vibration tester specifically designed to meet the demands of maintenance professionals who require rapid identification and prioritization of mechanical issues. One of the standout features of the Fluke 810 is its built-in diagnostic software, which significantly enhances its diagnostic capabilities. This software allows users to determine the severity and root cause of mechanical problems, thus enabling more effective and timely maintenance interventions. In terms of measurement capabilities, the Fluke 810 excels with its ability to measure a wide range of vibration parameters including overall vibration, bearing condition, and specific frequencies. It is equipped with a triaxial accelerometer that ensures precise and reliable measurements, which are crucial for accurate diagnostics. Additionally, the device offers a frequency range up to 20 kHz, making it suitable for a variety of industrial applications. The display features of the Fluke 810 are designed for user convenience and clarity. It boasts a large, high-resolution LCD screen that provides clear and detailed readouts of diagnostic data. The intuitive interface facilitates easy navigation through various diagnostic functions, ensuring that even less experienced users can operate the device effectively. The display also supports multiple languages, further broadening its accessibility. Connectivity is another key area where the Fluke 810 shines. The device is equipped with USB and RS-232 ports, allowing for seamless data transfer to computers and other devices. This connectivity enables maintenance professionals to easily document and share diagnostic results, which can be invaluable for collaborative troubleshooting and historical data analysis. Moreover, the Fluke 810 supports firmware updates, ensuring that users always have access to the latest features and improvements. By leveraging these advanced features and robust specifications, the Fluke 810 enhances maintenance workflows and significantly improves equipment reliability. Whether it’s diagnosing the root cause of a mechanical issue or determining the severity of a problem, the Fluke 810 provides maintenance professionals with the tools they need to keep their operations running smoothly and efficiently. Effective Training for Optimal Use of the Fluke 810 The Fluke 810 is an advanced vibration tester designed to provide precise diagnostic data. However, to fully harness its capabilities, a structured training program is essential. Effective training encompasses both theoretical knowledge and practical skills, ensuring users can operate the device with confidence and accuracy. Understanding the fundamentals of vibration analysis is the cornerstone of any effective training program. This involves grasping the basic principles of how vibrations work, the types of vibrations detected, and the significance of various vibration patterns. Users should become proficient in interpreting the diagnostic results provided by the Fluke 810, which includes recognizing common faults such as misalignment, imbalance, and looseness. Hands-on training is equally crucial. Practical modules should focus on real-world scenarios where users can practice setting up the Fluke 810, capturing data, and performing actual diagnostics. This experiential learning approach helps users to become adept at identifying issues and executing corrective actions effectively. The ability to translate theoretical knowledge into practical skills is vital for maximizing the device’s utility in maintenance operations. Selecting the right training provider is another critical component. Look for providers with a proven track record, comprehensive curriculum, and experienced instructors. Additionally, leveraging online resources such as webinars, tutorials, and forums can supplement formal training programs. Online platforms often provide updated content, ensuring learners remain informed about the latest advancements in vibration testing technology. Continuous learning and periodic refresher courses are key to maintaining proficiency. The field of vibration analysis and diagnostic tools is constantly evolving, and staying updated with new techniques and technologies is essential. Encouraging a culture of continuous improvement within the maintenance team will not only enhance their skills but also lead to more efficient and effective use of the Fluke 810. In conclusion, a well-rounded training program that combines theoretical knowledge, hands-on practice, and continuous learning is essential for optimizing the use of the Fluke 810. By investing in comprehensive training, users can significantly enhance their diagnostic capabilities, ultimately leading to improved maintenance outcomes and operational efficiency.

810 Vibration Tester Plus Training program book Order #: 810/ TRNG Mfg #: 4878251

Overview of Monarch Instruments Monarch Instruments is a distinguished manufacturer of precision measurement tools, serving a multitude of industrial sectors with unmatched expertise and innovation. Established with a mission to deliver accuracy and reliability, Monarch Instruments has consistently set industry standards through its advanced technological integrations. The company’s extensive range of products, including digital tachometers, stroboscopes, and data loggers, exemplifies its commitment to providing high-quality solutions that cater to the nuanced demands of modern measurements. Tracing its roots back to its inception, Monarch Instruments has evolved from a small-scale operation into a global leader in the measurement tools industry. The company prides itself on its ability to adapt and incorporate cutting-edge technology into its product lineup. Digital tachometers, for instance, are essential instruments in monitoring rotational speeds with high precision, while stroboscopes offer unparalleled accuracy in observing and analyzing motion. Data loggers, another critical product in their portfolio, ensure meticulous recording and monitoring of various environmental parameters. The versatility of Monarch Instruments’ products makes them indispensable across a wide array of industries. In the automotive sector, these tools are crucial for engine diagnostics and performance tuning. The aerospace industry relies on Monarch Instruments for precise measurements in aircraft maintenance and testing. Similarly, in manufacturing, these instruments play a vital role in quality control and process optimization. Each sector benefits immensely from the reliability and precision that Monarch Instruments guarantees. Monarch Instruments’ dedication to innovation is evident in their ongoing efforts to enhance product capabilities and user experiences. By integrating advanced digital technologies and maintaining stringent quality control processes, the company ensures that every instrument meets the highest standards of accuracy and durability. This unwavering commitment to excellence positions Monarch Instruments as a trusted partner for industries seeking dependable measurement solutions. Key Products and Their Applications Monarch Instruments has established itself as a leading provider of precision measurement tools, catering to a wide range of industrial and research applications. Among their flagship products, the ACT-3X Digital Tachometer, Nova-Pro LED Stroboscope, and Track-It Data Logger stand out due to their advanced features and reliable performance. ACT-3X Digital Tachometer The ACT-3X Digital Tachometer is a state-of-the-art device designed for measuring rotational speed. This digital tachometer boasts high accuracy with a measurement range from 0.5 to 999,990 RPM. Its ergonomic design includes a large, backlit LCD screen, making it easy to read measurements in various lighting conditions. The ACT-3X is commonly used in monitoring the rotational speed of engines, turbines, and other machinery components, ensuring optimal performance and preventing mechanical failures. Nova-Pro LED Stroboscope The Nova-Pro LED Stroboscope is another key product from Monarch Instruments. This portable device uses LED technology to provide bright and consistent illumination, allowing for the inspection of moving parts in machinery. It features adjustable flash rates and a high-resolution display, facilitating precise synchronization with the object’s motion. The stroboscope is invaluable in maintenance and quality control processes, enabling technicians to detect abnormalities such as misalignments or wear in rotating equipment. Track-It Data Logger The Track-It Data Logger is designed for recording environmental data over extended periods. Available in various models, it can monitor parameters such as temperature, humidity, pressure, and voltage. Its compact size and robust construction make it suitable for use in harsh environments, including research labs, manufacturing plants, and outdoor settings. The data logger is equipped with a high-capacity memory and user-friendly software for data analysis, making it an essential tool for scientists and engineers who require accurate and reliable data collection. Monarch Instruments incorporates innovative technologies in their products, such as advanced sensor integration and user-friendly interfaces, which set them apart from competitors. For instance, the ACT-3X utilizes a laser sensor for non-contact measurement, enhancing safety and convenience. The Nova-Pro LED Stroboscope’s use of energy-efficient LEDs extends battery life and reduces maintenance costs. The Track-It Data Logger’s wireless connectivity options enable remote monitoring and data transfer, increasing operational efficiency. Customer testimonials and case studies further illustrate the effectiveness and reliability of Monarch Instruments. For example, a leading automotive manufacturer reported significant improvements in engine performance monitoring using the ACT-3X Digital Tachometer. Another case study highlighted how a pharmaceutical company utilized the Nova-Pro LED Stroboscope to enhance the inspection process, reducing downtime and maintenance costs. Environmental researchers have also praised the Track-It Data Logger for its accuracy and durability in field studies.

Overview of Monarch Instruments Monarch Instruments is a distinguished manufacturer of precision measurement tools, serving a multitude of industrial sectors with unmatched expertise and innovation. Established with a mission to deliver accuracy and reliability, Monarch Instruments has consistently set industry standards through its advanced technological integrations. The company’s extensive range of products, including digital tachometers, stroboscopes, and data loggers, exemplifies its commitment to providing high-quality solutions that cater to the nuanced demands of modern measurements. Tracing its roots back to its inception, Monarch Instruments has evolved from a small-scale operation into a global leader in the measurement tools industry. The company prides itself on its ability to adapt and incorporate cutting-edge technology into its product lineup. Digital tachometers, for instance, are essential instruments in monitoring rotational speeds with high precision, while stroboscopes offer unparalleled accuracy in observing and analyzing motion. Data loggers, another critical product in their portfolio, ensure meticulous recording and monitoring of various environmental parameters. The versatility of Monarch Instruments’ products makes them indispensable across a wide array of industries. In the automotive sector, these tools are crucial for engine diagnostics and performance tuning. The aerospace industry relies on Monarch Instruments for precise measurements in aircraft maintenance and testing. Similarly, in manufacturing, these instruments play a vital role in quality control and process optimization. Each sector benefits immensely from the reliability and precision that Monarch Instruments guarantees. Monarch Instruments’ dedication to innovation is evident in their ongoing efforts to enhance product capabilities and user experiences. By integrating advanced digital technologies and maintaining stringent quality control processes, the company ensures that every instrument meets the highest standards of accuracy and durability. This unwavering commitment to excellence positions Monarch Instruments as a trusted partner for industries seeking dependable measurement solutions. Key Products and Their Applications Monarch Instruments has established itself as a leading provider of precision measurement tools, catering to a wide range of industrial and research applications. Among their flagship products, the ACT-3X Digital Tachometer, Nova-Pro LED Stroboscope, and Track-It Data Logger stand out due to their advanced features and reliable performance. ACT-3X Digital Tachometer The ACT-3X Digital Tachometer is a state-of-the-art device designed for measuring rotational speed. This digital tachometer boasts high accuracy with a measurement range from 0.5 to 999,990 RPM. Its ergonomic design includes a large, backlit LCD screen, making it easy to read measurements in various lighting conditions. The ACT-3X is commonly used in monitoring the rotational speed of engines, turbines, and other machinery components, ensuring optimal performance and preventing mechanical failures. Nova-Pro LED Stroboscope The Nova-Pro LED Stroboscope is another key product from Monarch Instruments. This portable device uses LED technology to provide bright and consistent illumination, allowing for the inspection of moving parts in machinery. It features adjustable flash rates and a high-resolution display, facilitating precise synchronization with the object’s motion. The stroboscope is invaluable in maintenance and quality control processes, enabling technicians to detect abnormalities such as misalignments or wear in rotating equipment. Track-It Data Logger The Track-It Data Logger is designed for recording environmental data over extended periods. Available in various models, it can monitor parameters such as temperature, humidity, pressure, and voltage. Its compact size and robust construction make it suitable for use in harsh environments, including research labs, manufacturing plants, and outdoor settings. The data logger is equipped with a high-capacity memory and user-friendly software for data analysis, making it an essential tool for scientists and engineers who require accurate and reliable data collection. Monarch Instruments incorporates innovative technologies in their products, such as advanced sensor integration and user-friendly interfaces, which set them apart from competitors. For instance, the ACT-3X utilizes a laser sensor for non-contact measurement, enhancing safety and convenience. The Nova-Pro LED Stroboscope’s use of energy-efficient LEDs extends battery life and reduces maintenance costs. The Track-It Data Logger’s wireless connectivity options enable remote monitoring and data transfer, increasing operational efficiency. Customer testimonials and case studies further illustrate the effectiveness and reliability of Monarch Instruments. For example, a leading automotive manufacturer reported significant improvements in engine performance monitoring using the ACT-3X Digital Tachometer. Another case study highlighted how a pharmaceutical company utilized the Nova-Pro LED Stroboscope to enhance the inspection process, reducing downtime and maintenance costs. Environmental researchers have also praised the Track-It Data Logger for its accuracy and durability in field studies.

Vibration Strobe CSI Kit 115/230V for model 2120 only Order #: 6220-031 Mfg #: 6220-031

No products in the cart.