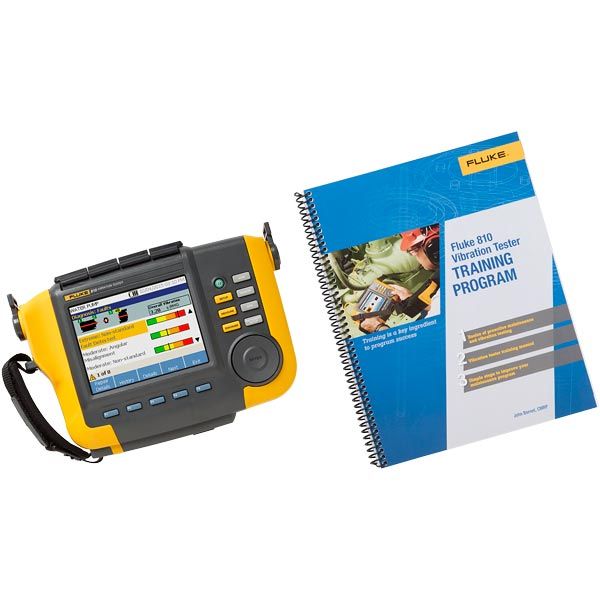

Fluke 810 Vibration Analysis

$5.834Introduction to Fluke Vibration Fluke vibration refers to the measurement and analysis of mechanical vibrations using specialized tools and equipment developed by Fluke, a globally recognized leader in precision measurement technology. Vibration measurement is a critical aspect of predictive maintenance and condition monitoring in various industries, including manufacturing, aerospace, and energy. Understanding the principles of vibration measurement involves recognizing how oscillatory motions in machinery components can indicate potential failures or inefficiencies. Accurate vibration analysis is essential for maintaining the health of machinery. It helps in early detection of mechanical issues such as misalignment, imbalance, bearing failures, and gear defects. By identifying these problems early, maintenance teams can prevent costly downtime and extend the lifespan of equipment. Fluke’s vibration measurement tools are known for their reliability and precision, making them indispensable in the toolkit of maintenance professionals. The basic principles of vibration measurement include the detection of amplitude, frequency, and phase of the oscillatory motion. These parameters are captured using accelerometers, which convert mechanical vibrations into electrical signals. The data is then analyzed to diagnose the condition of the machinery. Fluke provides a range of vibration measurement tools, including portable vibration testers, vibration meters, and sophisticated vibration analyzers, each designed to cater to different levels of diagnostic needs. Fluke’s dedication to innovation and quality makes their vibration analysis tools effective in detecting and diagnosing mechanical issues with high accuracy. Their equipment is engineered to withstand harsh industrial environments, ensuring durability and consistent performance. The importance of accurate vibration analysis in predictive maintenance cannot be overstated, as it contributes significantly to the operational efficiency and reliability of industrial machinery. Applications and Benefits of Fluke Vibration Analysis Fluke vibration analysis has become an indispensable tool across various industries, including manufacturing, automotive, aerospace, and energy. In manufacturing, for instance, vibration analysis is critical in monitoring the condition of machinery. By identifying early signs of wear and tear, maintenance teams can prevent equipment failure, thereby reducing downtime and extending the life of machinery. This proactive approach not only enhances productivity but also leads to significant cost savings. In the automotive sector, Fluke vibration analysis is used extensively to diagnose issues within vehicle components. From engine imbalances to misaligned driveshafts, the precision of vibration analysis ensures that potential problems are detected and rectified before they escalate. This results in improved vehicle performance and reliability, reinforcing customer satisfaction and reducing warranty claims. The aerospace industry also benefits significantly from vibration analysis. Aircraft components are subject to stringent safety and performance standards, and Fluke vibration tools provide the accuracy needed to meet these requirements. By regularly monitoring the vibration levels of critical parts such as turbines and rotors, maintenance teams can ensure the safety and efficiency of aircraft operations. This not only mitigates the risk of in-flight failures but also optimizes maintenance schedules. In the energy sector, particularly in power plants and wind farms, vibration analysis plays a pivotal role in the maintenance of turbines and generators. Fluke vibration tools help in detecting anomalies such as bearing failures and misalignments, which can lead to catastrophic failures if left unchecked. By integrating vibration analysis into routine maintenance programs, energy companies can enhance the reliability of their operations and achieve substantial cost savings. Case studies have demonstrated the tangible benefits of implementing Fluke vibration tools. For instance, a manufacturing plant reported a 30% reduction in unplanned downtime and a 20% increase in machinery life after incorporating vibration analysis into their maintenance strategy. Similarly, an automotive company experienced a 25% decrease in warranty claims by utilizing vibration diagnostics to enhance vehicle quality. Best practices for integrating Fluke vibration analysis into routine maintenance programs include regular training for maintenance personnel to ensure effective use of the tools. Continuous monitoring and data analysis are also essential to identify trends and make informed maintenance decisions. By fostering a culture of proactive maintenance, companies can maximize the benefits of Fluke vibration analysis, ultimately leading to improved operational efficiency and cost-effectiveness.