-

$1.193

Introduction to Branson CPX The Branson CPX is a state-of-the-art ultrasonic cleaning and processing system designed to deliver high efficiency and precision in various industrial applications. Developed by Branson, a leader in ultrasonic technology, the CPX series represents a significant advancement in the field of ultrasonic cleaning and welding. This versatile system is engineered to meet the rigorous demands of industries ranging from medical and aerospace to automotive and electronics. The primary purpose of the Branson CPX is to provide reliable and effective cleaning solutions. Utilizing ultrasonic waves, the CPX system can remove contaminants from intricate and delicate components that traditional cleaning methods might fail to address. This makes it an indispensable tool in maintaining the integrity and performance of precision parts and equipment. Furthermore, the Branson CPX is also adept at welding applications, where it ensures strong and durable bonds through ultrasonic energy. One of the standout features of the Branson CPX is its advanced design which incorporates digital controls, precise temperature regulation, and programmable settings. These features allow users to customize the cleaning or welding processes to suit specific requirements, enhancing overall efficiency. The CPX system is also equipped with a self-diagnostic function, ensuring optimal performance and reducing downtime. The history of the Branson CPX is rooted in continuous innovation. Branson has been at the forefront of ultrasonic technology for decades, consistently pushing the boundaries to develop solutions that address the evolving needs of various industries. The CPX series is a testament to this commitment, offering a blend of reliability, precision, and user-friendly operation. In industrial settings, the importance of the Branson CPX cannot be overstated. Its ability to improve efficiency and precision in processes such as cleaning and welding has a direct impact on productivity and quality. By leveraging ultrasonic technology, the CPX system ensures that components are cleaned or welded to the highest standards, thereby supporting the stringent requirements of modern manufacturing and maintenance operations. Applications and Benefits of Branson CPX The Branson CPX is a versatile tool that finds widespread application across various industries due to its advanced technology and robust performance. In the manufacturing sector, the Branson CPX is extensively used for precision cleaning of components. Its ultrasonic cleaning capabilities ensure that even the smallest particles are removed, leading to higher quality products and reduced defect rates. This is particularly important in industries that demand high precision, such as aerospace and medical device manufacturing. In the healthcare sector, the Branson CPX plays a crucial role in the sterilization and maintenance of medical instruments. The ultrasonic cleaning process effectively removes contaminants that traditional cleaning methods might miss, thereby ensuring the highest standards of hygiene and patient safety. This makes the Branson CPX an invaluable asset in hospitals, clinics, and laboratories. The electronics industry also benefits significantly from the Branson CPX. The cleaning of circuit boards and electronic components is a critical step in the production process. The ultrasonic waves generated by the Branson CPX can reach intricate and minute spaces, removing flux residues and other contaminants that could potentially cause malfunctions. This results in higher reliability and longevity of electronic devices. In the automotive industry, the Branson CPX is used for both cleaning and welding applications. Ultrasonic welding with the Branson CPX ensures strong and precise joins, which is essential for both safety and performance. Additionally, the cleaning capabilities of the CPX help in maintaining the quality and functionality of automotive parts, leading to better overall vehicle performance. The benefits of using the Branson CPX are numerous. Enhanced cleaning capabilities ensure thorough decontamination, which is crucial for maintaining high standards across various sectors. Improved weld quality provided by the CPX leads to stronger, more reliable products. Furthermore, the increased operational efficiency afforded by the Branson CPX translates to cost savings and higher productivity for businesses. A notable case study highlighting the impact of the Branson CPX is its implementation in a leading electronics manufacturing company. By integrating the CPX into their cleaning process, the company reported a significant reduction in product failure rates and an improvement in overall product quality. This success story exemplifies how the Branson CPX can bring about tangible benefits in real-world scenarios.

-

$1.255

Introduction to Branson CPX The Branson CPX is a state-of-the-art ultrasonic cleaning and processing system designed to deliver high efficiency and precision in various industrial applications. Developed by Branson, a leader in ultrasonic technology, the CPX series represents a significant advancement in the field of ultrasonic cleaning and welding. This versatile system is engineered to meet the rigorous demands of industries ranging from medical and aerospace to automotive and electronics. The primary purpose of the Branson CPX is to provide reliable and effective cleaning solutions. Utilizing ultrasonic waves, the CPX system can remove contaminants from intricate and delicate components that traditional cleaning methods might fail to address. This makes it an indispensable tool in maintaining the integrity and performance of precision parts and equipment. Furthermore, the Branson CPX is also adept at welding applications, where it ensures strong and durable bonds through ultrasonic energy. One of the standout features of the Branson CPX is its advanced design which incorporates digital controls, precise temperature regulation, and programmable settings. These features allow users to customize the cleaning or welding processes to suit specific requirements, enhancing overall efficiency. The CPX system is also equipped with a self-diagnostic function, ensuring optimal performance and reducing downtime. The history of the Branson CPX is rooted in continuous innovation. Branson has been at the forefront of ultrasonic technology for decades, consistently pushing the boundaries to develop solutions that address the evolving needs of various industries. The CPX series is a testament to this commitment, offering a blend of reliability, precision, and user-friendly operation. In industrial settings, the importance of the Branson CPX cannot be overstated. Its ability to improve efficiency and precision in processes such as cleaning and welding has a direct impact on productivity and quality. By leveraging ultrasonic technology, the CPX system ensures that components are cleaned or welded to the highest standards, thereby supporting the stringent requirements of modern manufacturing and maintenance operations. Applications and Benefits of Branson CPX The Branson CPX is a versatile tool that finds widespread application across various industries due to its advanced technology and robust performance. In the manufacturing sector, the Branson CPX is extensively used for precision cleaning of components. Its ultrasonic cleaning capabilities ensure that even the smallest particles are removed, leading to higher quality products and reduced defect rates. This is particularly important in industries that demand high precision, such as aerospace and medical device manufacturing. In the healthcare sector, the Branson CPX plays a crucial role in the sterilization and maintenance of medical instruments. The ultrasonic cleaning process effectively removes contaminants that traditional cleaning methods might miss, thereby ensuring the highest standards of hygiene and patient safety. This makes the Branson CPX an invaluable asset in hospitals, clinics, and laboratories. The electronics industry also benefits significantly from the Branson CPX. The cleaning of circuit boards and electronic components is a critical step in the production process. The ultrasonic waves generated by the Branson CPX can reach intricate and minute spaces, removing flux residues and other contaminants that could potentially cause malfunctions. This results in higher reliability and longevity of electronic devices. In the automotive industry, the Branson CPX is used for both cleaning and welding applications. Ultrasonic welding with the Branson CPX ensures strong and precise joins, which is essential for both safety and performance. Additionally, the cleaning capabilities of the CPX help in maintaining the quality and functionality of automotive parts, leading to better overall vehicle performance. The benefits of using the Branson CPX are numerous. Enhanced cleaning capabilities ensure thorough decontamination, which is crucial for maintaining high standards across various sectors. Improved weld quality provided by the CPX leads to stronger, more reliable products. Furthermore, the increased operational efficiency afforded by the Branson CPX translates to cost savings and higher productivity for businesses. A notable case study highlighting the impact of the Branson CPX is its implementation in a leading electronics manufacturing company. By integrating the CPX into their cleaning process, the company reported a significant reduction in product failure rates and an improvement in overall product quality. This success story exemplifies how the Branson CPX can bring about tangible benefits in real-world scenarios.

-

$1.533

Introduction to Branson CPX The Branson CPX is a state-of-the-art ultrasonic cleaning and processing system designed to deliver high efficiency and precision in various industrial applications. Developed by Branson, a leader in ultrasonic technology, the CPX series represents a significant advancement in the field of ultrasonic cleaning and welding. This versatile system is engineered to meet the rigorous demands of industries ranging from medical and aerospace to automotive and electronics. The primary purpose of the Branson CPX is to provide reliable and effective cleaning solutions. Utilizing ultrasonic waves, the CPX system can remove contaminants from intricate and delicate components that traditional cleaning methods might fail to address. This makes it an indispensable tool in maintaining the integrity and performance of precision parts and equipment. Furthermore, the Branson CPX is also adept at welding applications, where it ensures strong and durable bonds through ultrasonic energy. One of the standout features of the Branson CPX is its advanced design which incorporates digital controls, precise temperature regulation, and programmable settings. These features allow users to customize the cleaning or welding processes to suit specific requirements, enhancing overall efficiency. The CPX system is also equipped with a self-diagnostic function, ensuring optimal performance and reducing downtime. The history of the Branson CPX is rooted in continuous innovation. Branson has been at the forefront of ultrasonic technology for decades, consistently pushing the boundaries to develop solutions that address the evolving needs of various industries. The CPX series is a testament to this commitment, offering a blend of reliability, precision, and user-friendly operation. In industrial settings, the importance of the Branson CPX cannot be overstated. Its ability to improve efficiency and precision in processes such as cleaning and welding has a direct impact on productivity and quality. By leveraging ultrasonic technology, the CPX system ensures that components are cleaned or welded to the highest standards, thereby supporting the stringent requirements of modern manufacturing and maintenance operations. Applications and Benefits of Branson CPX The Branson CPX is a versatile tool that finds widespread application across various industries due to its advanced technology and robust performance. In the manufacturing sector, the Branson CPX is extensively used for precision cleaning of components. Its ultrasonic cleaning capabilities ensure that even the smallest particles are removed, leading to higher quality products and reduced defect rates. This is particularly important in industries that demand high precision, such as aerospace and medical device manufacturing. In the healthcare sector, the Branson CPX plays a crucial role in the sterilization and maintenance of medical instruments. The ultrasonic cleaning process effectively removes contaminants that traditional cleaning methods might miss, thereby ensuring the highest standards of hygiene and patient safety. This makes the Branson CPX an invaluable asset in hospitals, clinics, and laboratories. The electronics industry also benefits significantly from the Branson CPX. The cleaning of circuit boards and electronic components is a critical step in the production process. The ultrasonic waves generated by the Branson CPX can reach intricate and minute spaces, removing flux residues and other contaminants that could potentially cause malfunctions. This results in higher reliability and longevity of electronic devices. In the automotive industry, the Branson CPX is used for both cleaning and welding applications. Ultrasonic welding with the Branson CPX ensures strong and precise joins, which is essential for both safety and performance. Additionally, the cleaning capabilities of the CPX help in maintaining the quality and functionality of automotive parts, leading to better overall vehicle performance. The benefits of using the Branson CPX are numerous. Enhanced cleaning capabilities ensure thorough decontamination, which is crucial for maintaining high standards across various sectors. Improved weld quality provided by the CPX leads to stronger, more reliable products. Furthermore, the increased operational efficiency afforded by the Branson CPX translates to cost savings and higher productivity for businesses. A notable case study highlighting the impact of the Branson CPX is its implementation in a leading electronics manufacturing company. By integrating the CPX into their cleaning process, the company reported a significant reduction in product failure rates and an improvement in overall product quality. This success story exemplifies how the Branson CPX can bring about tangible benefits in real-world scenarios.

-

$700

FBcal12D technology represents an innovative approach to energy management, incorporating advanced computing capabilities and intelligent systems to optimize energy consumption and performance. The origin of this technology is found in the need for more efficient and sustainable ways of managing energy resources, within the context of ever-increasing demand and environmental challenges. Basic mechanism of FBcal12D technology is the use of sophisticated algorithms that process data in real time. These algorithms are designed to analyze energy consumption patterns and provide suggestions for improvements, taking into account factors such as demand, performance and environmental conditions. The sensors used in this technology collect data from various sources, such as temperature, humidity, and energy consumption, providing a comprehensive picture of operating conditions. The function of the FBcal12D technology is based on the interaction of these sensors with computer systems, which use the data to make real-time decisions. This allows the dynamic regulation of energy consumption, adapting the performance of the systems to the current needs. For example, in industrial applications, the technology can optimize the operation of machinery, reducing energy waste and increasing productivity. Examples of FBcal12D technology applications include industry, where it helps reduce energy costs and emissions, buildings, where it ensures the efficient operation of heating, cooling and lighting systems, and home systems, where it provides smart solutions to save energy . This technology is emerging as a powerful tool for modern energy management, promoting sustainability and improving energy efficiency in a variety of sectors.. Benefits and Prospects of FBcal12D Technology FBcal12D technology offers a wide range of benefits, which extend to both businesses and consumers. First of all, the improved energy management it offers can lead to significant cost reduction. Businesses can achieve higher performance through more efficient use of their resources, thereby reducing operating expenses. For consumers, FBcal12D technology can translate into lower energy bills, offering a more cost-effective solution to meet energy needs. The environmental impact of FBcal12D technology is equally important. The ability to reduce carbon emissions helps combat climate change by promoting sustainable development. The technology enables the optimal utilization of energy resources, reducing losses and minimizing the need for additional energy production. In this way, FBcal12D contributes to a greener and more environmentally friendly energy landscape. The future prospects of FBcal12D technology are extremely promising. The possibility of its development and application in new sectors, such as renewable energy sources and smart grids, opens new horizons for the energy industry. Integrating this technology into renewable energy systems can improve their efficiency and make renewables more competitive. In addition, its use in smart grids can lead to a more flexible and reliable energy infrastructure, able to meet modern demands.

-

$600

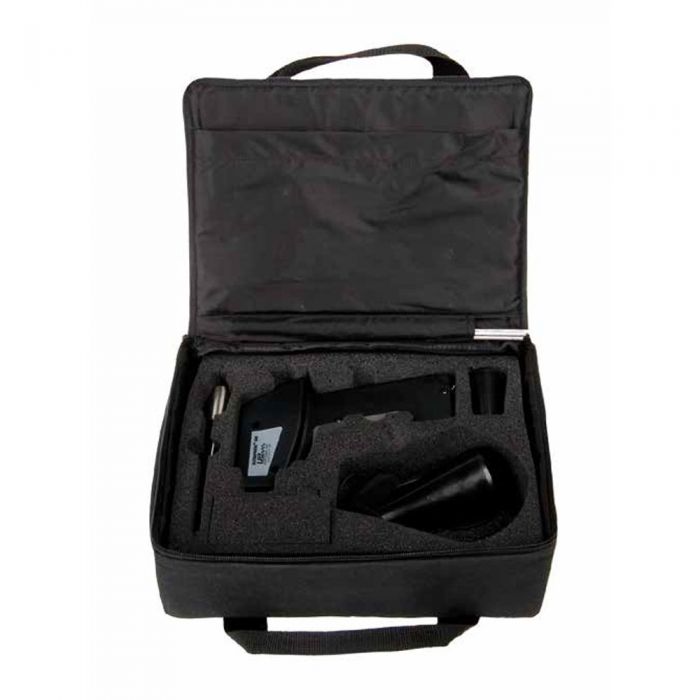

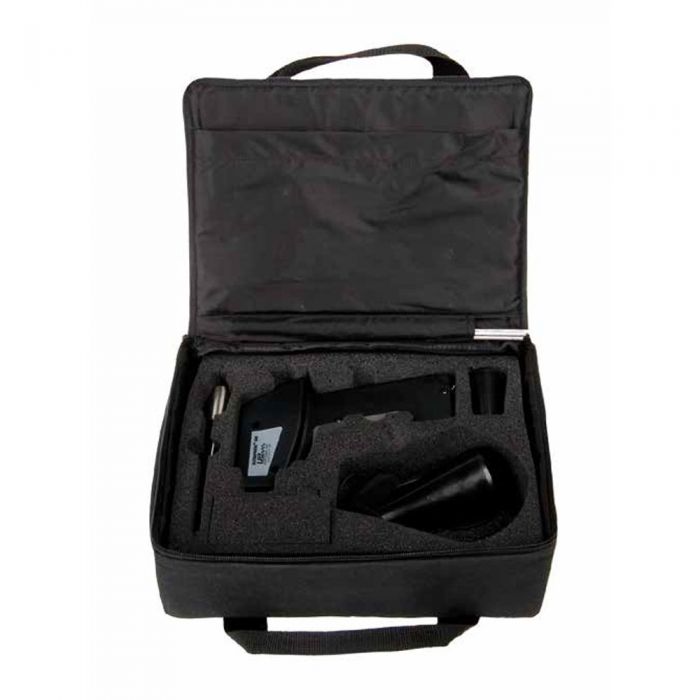

Introduction to the U.E. Systems UP100SC The U.E. Systems UP100SC is a state-of-the-art ultrasonic leak detection tool, specifically engineered to identify leaks in compressed air systems, steam traps, and various other industrial equipment. This advanced device is renowned for its precision, reliability, and user-friendly design, making it a preferred choice among maintenance professionals. The UP100SC is equipped with cutting-edge technology that not only enhances its detection capabilities but also simplifies the process, ensuring that even those with minimal training can effectively utilize it. One of the key features of the U.E. Systems UP100SC is its ergonomic design, which ensures comfort during extended use. The device is lightweight and easy to handle, minimizing user fatigue. Additionally, its intuitive interface allows for straightforward operation, making it accessible to users of all skill levels. The UP100SC also boasts advanced technology that provides accurate leak detection, which is crucial for maintaining the operational efficiency of industrial systems and reducing energy costs. Leak detection is of paramount importance in various industries. In manufacturing, for instance, undetected leaks in compressed air systems can lead to significant energy losses and increased operational costs. Similarly, in the automotive industry, ensuring that all systems are leak-free is vital for maintaining vehicle performance and safety standards. The chemical processing industry also greatly benefits from precise leak detection, as it helps prevent hazardous leaks that could pose safety risks and environmental concerns. Overall, the U.E. Systems UP100SC serves as an indispensable tool for industries aiming to enhance efficiency and reduce energy expenditures. Its user-friendly design and advanced features make it an essential component of any maintenance toolkit. By investing in such reliable leak detection technology, industries can ensure optimal performance and sustainability of their operations. How to Use the UP100SC for Effective Leak Detection Utilizing the U.E. Systems UP100SC for ultrasonic leak detection involves a structured approach to ensure accuracy and efficiency. Begin with the initial setup by powering on the device and attaching the appropriate sensor. The headset should be connected to allow for clear audio feedback of ultrasonic signals. Once the device is operational, start by scanning the area or equipment. Hold the UP100SC approximately 1-2 inches away from the surface, moving it slowly to detect any variations in the ultrasonic frequencies. The sensitivity can be adjusted to filter out ambient noise, ensuring that only relevant signals are captured. Interpreting the ultrasonic signals is crucial. The device’s display will show varying levels of decibels indicating the intensity of the detected leak. A higher decibel reading usually points toward a more significant leak. To pinpoint the exact location, fine-tune the sensitivity and narrow down the search area. Visual and audio cues from the UP100SC will guide you to the source. Regular maintenance checks are essential for the longevity and accuracy of the UP100SC. Ensure that the sensor and headset connections are secure and free from damage. Periodic calibration of the device is recommended to maintain its precision. Calibration can be done using reference standards provided by the manufacturer. Integrating the UP100SC into a predictive maintenance program can vastly improve operational efficiency. By routinely scanning critical equipment, potential leaks can be detected and rectified before escalating into costly repairs or downtime. Documenting findings is essential. Use the built-in data logging feature to record decibel levels, locations, and other relevant details for future reference. When scanning different types of equipment such as valves, compressors, and pipes, adjust the device settings to match the specific requirements. For instance, scanning a high-pressure valve may require a different sensitivity setting compared to a low-pressure pipe. Best practices include methodical sweeping of the area and cross-referencing audio and visual signals. If issues arise, such as inconsistent readings, refer to the troubleshooting guide provided by U.E. Systems. Common problems can often be resolved by re-calibrating the device or checking for sensor obstructions. Utilizing real-world examples, the UP100SC has proven effective in industries ranging from manufacturing to HVAC, showcasing its versatility and reliability in detecting leaks.