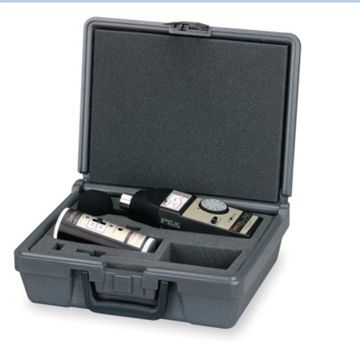

Simpson Electric 40006

$616Overview of the Simpson Electric 40006 Multimeter The Simpson Electric 40006 multimeter represents a blend of historical excellence and modern precision, encapsulating the legacy of the Simpson Electric Company. Founded in 1936, Simpson Electric has long been a pioneer in electrical measurement instruments. The 40006 model continues this tradition, offering robust design and reliable performance that has made it a staple in various industries. In terms of design and build quality, the Simpson Electric 40006 stands out with its sturdy construction and ergonomic design. It features an analog display that provides clear and immediate readings, a characteristic that many users find more intuitive compared to digital displays. The multimeter is built to withstand rigorous use, boasting a durable casing that protects it from damage in demanding environments. When it comes to technical specifications, the Simpson Electric 40006 does not disappoint. It offers a comprehensive measurement range that covers voltage, current, and resistance. With a high degree of accuracy, it ensures precise readings essential for both troubleshooting and detailed analysis. The multimeter’s reliability is further enhanced by its robust internal components capable of withstanding fluctuations and electrical surges, ensuring longevity and consistent performance. What sets the Simpson Electric 40006 apart are its primary features. The analog display is not only easy to read but also provides real-time feedback, which is crucial for monitoring dynamic electrical parameters. Its user-friendly interface makes it accessible to both seasoned professionals and novices, reducing the learning curve significantly. Additionally, the device’s reliability is a hallmark, making it a trusted tool in fields such as electrical engineering, automotive repair, and industrial maintenance. Industries that benefit from using the Simpson Electric 40006 multimeter are diverse. From manufacturing plants to automotive workshops, and from educational institutions to field service operations, this multimeter proves invaluable. Its versatility and dependability make it a preferred choice for professionals who require consistent and accurate electrical measurements. Using the Simpson Electric 40006 Multimeter Understanding the practical aspects of using the Simpson Electric 40006 multimeter is essential for accurate and efficient electrical measurements. To begin, ensure the device is properly set up by connecting the test leads to the appropriate ports. Typically, the black lead is connected to the common (COM) port, while the red lead is plugged into the port corresponding to the measurement type. Before taking any measurements, safety precautions must be observed. Always ensure the multimeter is in good working condition, and the test leads are intact. Never attempt to measure high voltage circuits without adequate knowledge and protective gear. Additionally, start by selecting the highest possible range on the multimeter to prevent damaging the device. The Simpson Electric 40006 multimeter offers various functions and settings. For voltage measurements, turn the dial to the ‘V’ setting and choose either AC or DC based on your requirements. Insert the test leads into the circuit and read the displayed value. For current measurements, switch to the ‘A’ setting, ensuring you break the circuit to place the leads in series with the load. Resistance measurements are performed by selecting the ‘Ω’ setting and placing the leads across the component being tested. Real-world applications of the multimeter include troubleshooting electrical circuits, testing batteries, and diagnosing appliance issues. For instance, to test a battery, set the multimeter to the appropriate DC voltage range and place the leads on the battery terminals. A reading close to the battery’s rated voltage indicates it is in good condition. To troubleshoot a faulty appliance, use the resistance function to check for continuity in wires and components. To maintain the Simpson Electric 40006 multimeter and ensure its longevity, regular calibration and proper storage are crucial. Calibration should be performed periodically, following the manufacturer’s guidelines to maintain measurement accuracy. Store the multimeter in a dry, cool place, away from direct sunlight and moisture, to prevent damage.