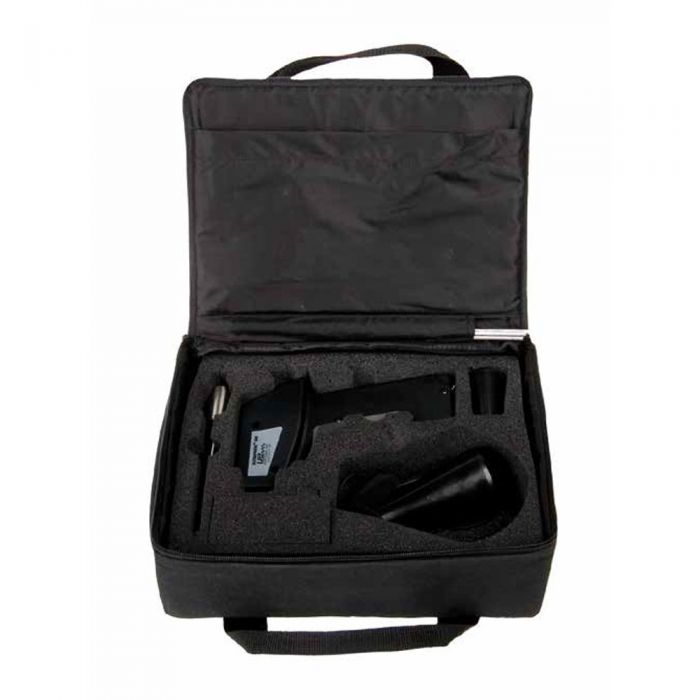

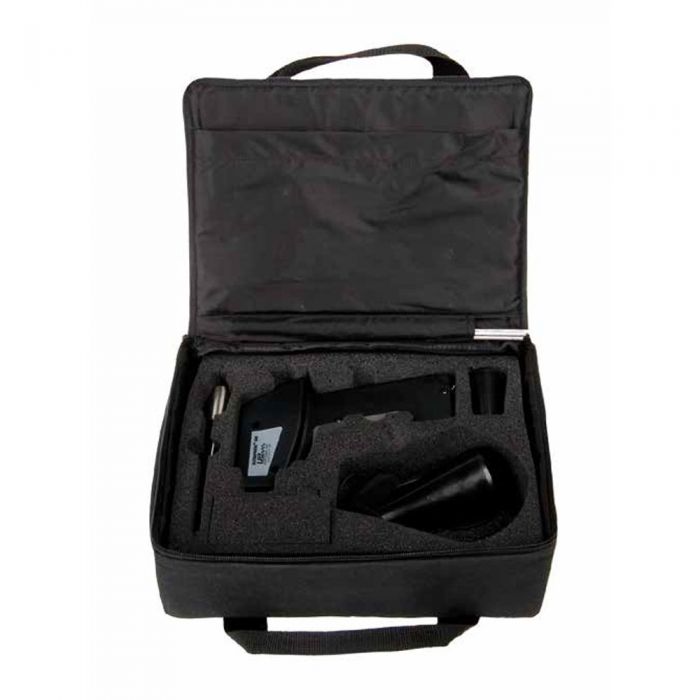

SPM Instrument MG4-2

$1.077Introduction to SPM Instruments Scanning Probe Microscopy (SPM) instruments constitute a critical advancement in the field of nanotechnology and material science. These instruments operate by scanning a physical probe over a specimen to measure various types of interactions between the probe and the sample surface. The primary principle behind SPM is to generate high-resolution images by detecting forces and currents at the nanoscale level. The physical components of SPM instruments typically include a sharp probe, a precise scanning system, and a detection system that records the probe’s interactions with the sample. The probe, often made of silicon or tungsten, is mounted on a cantilever, which moves across the sample surface. Variations in the height and other properties of the sample surface cause deflections in the cantilever, which are detected and measured to create a detailed image. SPM technology has a rich history, dating back to the early 1980s when Gerd Binnig and Heinrich Rohrer invented the Scanning Tunneling Microscope (STM). Their groundbreaking work earned them the Nobel Prize in Physics in 1986. STM paved the way for the development of other SPM techniques, such as Atomic Force Microscopy (AFM), introduced by Binnig, Quate, and Gerber in 1986. There are several types of SPM instruments, each suited for specific applications. Atomic Force Microscopy (AFM) is widely used to measure surface topography, mechanical properties, and even molecular interactions. AFM is particularly advantageous for its ability to operate in various environments, including air, liquid, and vacuum. On the other hand, Scanning Tunneling Microscopy (STM) is highly effective for imaging conductive surfaces at atomic resolution. STM relies on quantum tunneling of electrons between the probe and the sample, making it an excellent tool for studying electronic properties of materials. Other variants of SPM include Magnetic Force Microscopy (MFM), Electrostatic Force Microscopy (EFM), and Chemical Force Microscopy (CFM), each offering unique insights into different surface characteristics. The versatility and high resolution of SPM instruments make them indispensable tools in both research and industrial applications. Applications and Advancements in SPM Technology Scanning Probe Microscopy (SPM) instruments have become indispensable tools across various scientific and industrial domains, including materials science, biology, and nanotechnology. These powerful devices enable researchers to visualize and manipulate materials at the atomic and molecular levels, leading to groundbreaking discoveries and innovations. In materials science, SPM instruments are widely used to investigate the surface properties of materials. For instance, Atomic Force Microscopy (AFM), a type of SPM, allows scientists to study the topography, mechanical properties, and electrical characteristics of different materials. This has been pivotal in developing new materials with enhanced properties, such as stronger alloys and advanced polymers. One notable case study involves the use of AFM to examine the microstructural details of graphene, leading to significant advancements in the development of graphene-based electronics. In the field of biology, SPM techniques like AFM and Scanning Tunneling Microscopy (STM) have revolutionized our understanding of biological systems. These instruments provide detailed images of biological samples, including cells, viruses, and biomolecules, under physiological conditions. For example, AFM has been used to study the mechanical properties of cell membranes, offering insights into cellular processes and disease mechanisms. Nanotechnology is another area where SPM instruments have made profound contributions. SPM technologies facilitate the manipulation of nanoparticles and nanostructures with unprecedented precision. This capability is crucial for the development of nanoscale devices and materials with specific properties. An example is the use of STM to manipulate individual atoms on a surface, which has been instrumental in the creation of atomic-scale electronic devices. Recent advancements in SPM technology have significantly enhanced its capabilities. Improvements in resolution and speed have enabled the observation of dynamic processes at the atomic scale in real-time. Enhanced data analysis techniques, powered by artificial intelligence and machine learning, are providing deeper insights into complex datasets, making it easier to interpret the results of SPM experiments. Looking ahead, the future of SPM technology holds exciting potential. Emerging trends include the integration of SPM with other analytical techniques, such as spectroscopy and electron microscopy, to provide complementary information. Advances in automation and miniaturization are expected to make SPM instruments more accessible and user-friendly, expanding their application range. Additionally, ongoing research aims to develop SPM instruments capable of operating in extreme environments, opening new frontiers in space exploration and deep-sea research.