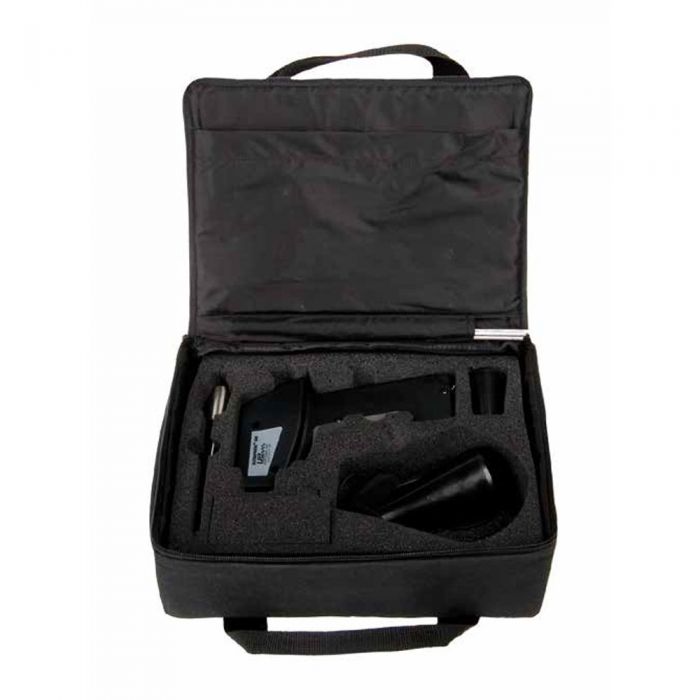

Megger 569001-KIT

$1.706Introduction to the Megger 569001-KIT The Megger 569001-KIT is a multifunctional electrical testing kit meticulously designed for professionals in the electrical and telecommunications fields. This robust kit is engineered to deliver comprehensive testing solutions, ensuring electrical safety and system integrity. The Megger 569001-KIT stands out due to its reliability and accuracy, making it an indispensable tool for electricians, engineers, and maintenance personnel. At the heart of this kit is the insulation resistance tester, a critical instrument that assesses the insulation quality of electrical components, identifying potential faults that could lead to system failures or safety hazards. Complementing this is the continuity tester, which verifies the integrity of electrical connections, ensuring seamless operation of circuits and systems. Together, these tools provide a thorough analysis of electrical systems, enhancing preventive maintenance and troubleshooting efficacy. The Megger 569001-KIT’s specifications underscore its versatility and precision. It boasts a wide measurement range, high accuracy, and user-friendly interface, making it suitable for a variety of applications. Furthermore, the kit includes additional essential tools such as test leads, probes, and connectors, all designed to streamline the testing process and deliver precise results. This testing kit finds extensive application across numerous industries. In the telecommunications sector, it aids in maintaining the integrity of complex networks, ensuring uninterrupted communication services. In the electrical industry, it is pivotal in the installation, maintenance, and troubleshooting of electrical systems, safeguarding both equipment and personnel. The reliability and accuracy of the Megger 569001-KIT make it a trusted choice for professionals who demand excellence in their testing equipment. In summary, the Megger 569001-KIT is a comprehensive and reliable solution for electrical and telecommunications testing. Its multifunctional capabilities, coupled with its precision and ease of use, make it an essential tool for ensuring the safety and integrity of electrical systems. Practical Applications and Benefits of Using the Megger 569001-KIT The Megger 569001-KIT is a versatile tool that plays a crucial role in various electrical testing scenarios. One of its primary applications is in testing insulation resistance across different settings. In residential environments, electricians use this kit to ensure that household wiring systems are free from faults that could lead to electrical fires or short circuits. In commercial buildings, the kit is employed to maintain the integrity of complex electrical networks, which is vital for the safe operation of businesses. Industrial applications benefit from the Megger 569001-KIT by using it to test the insulation of heavy machinery and equipment, preventing costly downtimes and ensuring worker safety. Another significant application is verifying continuity in electrical circuits. By ensuring that electrical paths are uninterrupted, the Megger 569001-KIT helps prevent potential hazards and ensures that systems function as intended. This is particularly useful in scenarios where circuit integrity is critical, such as in control panels and distribution boards. The Megger 569001-KIT also proves invaluable in diagnosing faults in telecommunications lines. Technicians rely on it to identify issues such as line breaks, poor connections, and insulation defects, ensuring seamless communication and data transfer. This versatility makes it a preferred choice among professionals in various fields. The benefits of using the Megger 569001-KIT are manifold. Improved accuracy in measurements is a standout feature, allowing technicians to pinpoint issues with a high degree of precision. Enhanced safety is another significant advantage, as the kit’s robust design and reliable performance minimize the risk of accidents during testing. Additionally, the efficiency gained from using this kit cannot be overstated. Technicians can troubleshoot and resolve electrical issues more quickly, reducing downtime and associated costs. Real-world examples underscore the reliability of the Megger 569001-KIT. For instance, a commercial electrician reported that using the kit reduced troubleshooting time by 50%, allowing for faster resolution of electrical faults. Similarly, an industrial maintenance team noted a significant decrease in equipment failure rates after regularly employing the kit for preventive maintenance checks.