Fluke 810/+TRNG

$5.308 & Free Shipping

Free shipping on orders over $50!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

Description

Understanding the Fluke 810: Features and Specifications

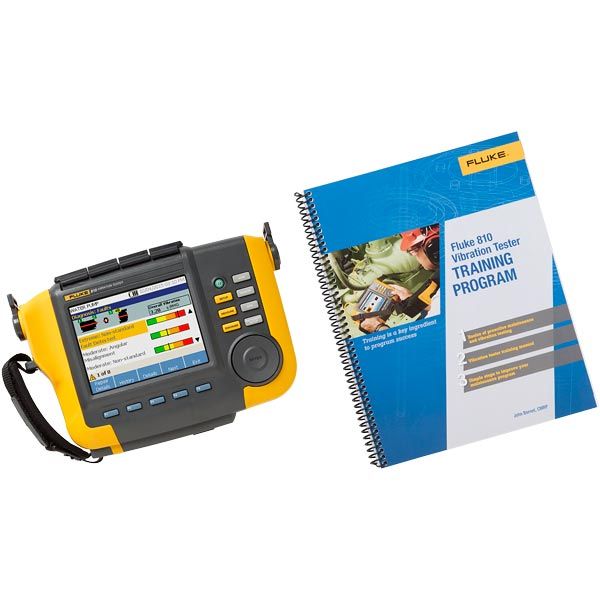

The Fluke 810 is a sophisticated vibration tester specifically designed to meet the demands of maintenance professionals who require rapid identification and prioritization of mechanical issues. One of the standout features of the Fluke 810 is its built-in diagnostic software, which significantly enhances its diagnostic capabilities. This software allows users to determine the severity and root cause of mechanical problems, thus enabling more effective and timely maintenance interventions.

In terms of measurement capabilities, the Fluke 810 excels with its ability to measure a wide range of vibration parameters including overall vibration, bearing condition, and specific frequencies. It is equipped with a triaxial accelerometer that ensures precise and reliable measurements, which are crucial for accurate diagnostics. Additionally, the device offers a frequency range up to 20 kHz, making it suitable for a variety of industrial applications.

The display features of the Fluke 810 are designed for user convenience and clarity. It boasts a large, high-resolution LCD screen that provides clear and detailed readouts of diagnostic data. The intuitive interface facilitates easy navigation through various diagnostic functions, ensuring that even less experienced users can operate the device effectively. The display also supports multiple languages, further broadening its accessibility.

Connectivity is another key area where the Fluke 810 shines. The device is equipped with USB and RS-232 ports, allowing for seamless data transfer to computers and other devices. This connectivity enables maintenance professionals to easily document and share diagnostic results, which can be invaluable for collaborative troubleshooting and historical data analysis. Moreover, the Fluke 810 supports firmware updates, ensuring that users always have access to the latest features and improvements.

By leveraging these advanced features and robust specifications, the Fluke 810 enhances maintenance workflows and significantly improves equipment reliability. Whether it’s diagnosing the root cause of a mechanical issue or determining the severity of a problem, the Fluke 810 provides maintenance professionals with the tools they need to keep their operations running smoothly and efficiently.

Effective Training for Optimal Use of the Fluke 810

The Fluke 810 is an advanced vibration tester designed to provide precise diagnostic data. However, to fully harness its capabilities, a structured training program is essential. Effective training encompasses both theoretical knowledge and practical skills, ensuring users can operate the device with confidence and accuracy.

Understanding the fundamentals of vibration analysis is the cornerstone of any effective training program. This involves grasping the basic principles of how vibrations work, the types of vibrations detected, and the significance of various vibration patterns. Users should become proficient in interpreting the diagnostic results provided by the Fluke 810, which includes recognizing common faults such as misalignment, imbalance, and looseness.

Hands-on training is equally crucial. Practical modules should focus on real-world scenarios where users can practice setting up the Fluke 810, capturing data, and performing actual diagnostics. This experiential learning approach helps users to become adept at identifying issues and executing corrective actions effectively. The ability to translate theoretical knowledge into practical skills is vital for maximizing the device’s utility in maintenance operations.

Selecting the right training provider is another critical component. Look for providers with a proven track record, comprehensive curriculum, and experienced instructors. Additionally, leveraging online resources such as webinars, tutorials, and forums can supplement formal training programs. Online platforms often provide updated content, ensuring learners remain informed about the latest advancements in vibration testing technology.

Continuous learning and periodic refresher courses are key to maintaining proficiency. The field of vibration analysis and diagnostic tools is constantly evolving, and staying updated with new techniques and technologies is essential. Encouraging a culture of continuous improvement within the maintenance team will not only enhance their skills but also lead to more efficient and effective use of the Fluke 810.

In conclusion, a well-rounded training program that combines theoretical knowledge, hands-on practice, and continuous learning is essential for optimizing the use of the Fluke 810. By investing in comprehensive training, users can significantly enhance their diagnostic capabilities, ultimately leading to improved maintenance outcomes and operational efficiency.